Polymers, Free Full-Text

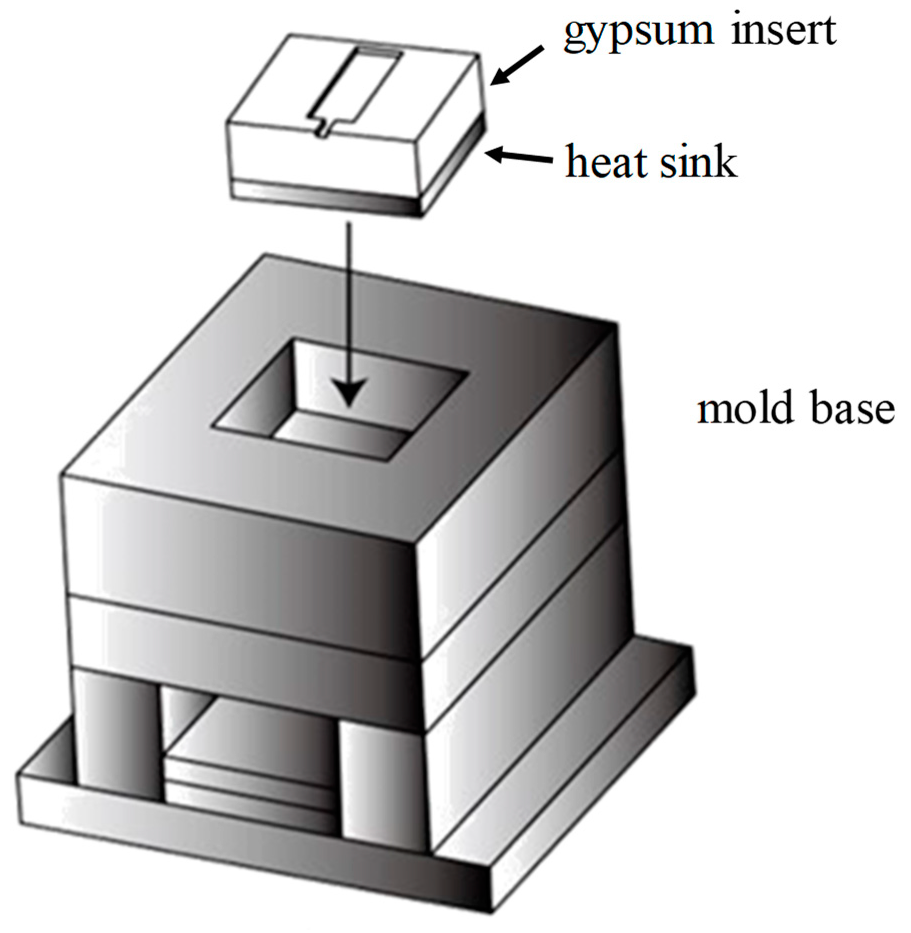

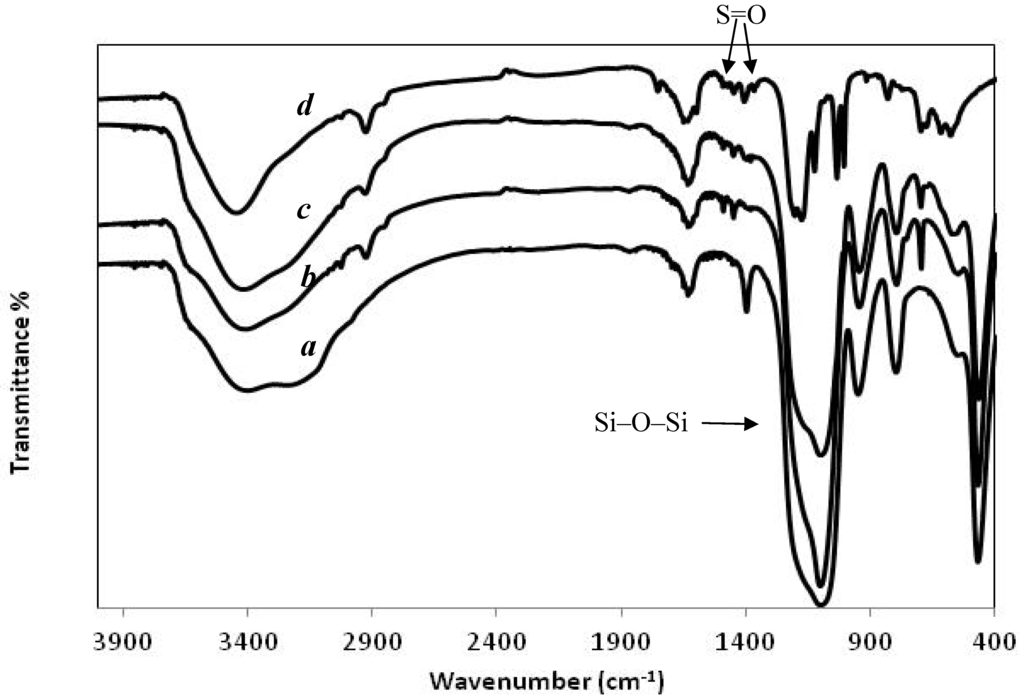

Gypsum molds have been developed as an alternative for the Rapid tooling (RT) method used in injection molding. However, the poor capability of the heat delivery forces the gypsum mold to operate under a high-risk condition, and distortion of the molded part becomes apparent. The goal is to investigate the effect of a heat sink on the reduction of the gypsum mold temperature and to establish a methodology for the heat sink design. The methodology used the advantage of the electrical circuit concept to analyze the mold temperature. The heat transfer of a mold was modeled using an equivalent thermal circuit. After all the components on the circuit were determined, the heat transfer rate could then be calculated. Once the heat transfer rate was known, the mold temperature could be easily analyzed. A modified thermal circuit considering transverse heat conduction was also proposed, which estimated the mold temperature more accurately. The mold temperature was reduced by 16.8 °C when a gypsum mold was installed with a 40 mm thick heat sink in a parallel configuration. Moreover, the reduction of the mold temperature improved the deflection of the molded part from 0.78 mm to 0.54 mm. This work provides a quick approach to analyze the mold temperature based on the thermal circuit concept. As the cooling system of the mold was modularized analytically, important properties of the cooling system in the heat transfer process were revealed by analyzing the thermal circuit of the mold, for example, the heat transfer rate or the mold temperature.

Polymers, Free Full-Text

Polymers, Free Full-Text, 3d Printer Lubricant

Polymers, Free Full-Text, passfeder 5mm

Polymers, Free Full-Text, códigos de double xp no block street

Polymers, Free Full-Text

PPT - Polymers PowerPoint Presentation, free download - ID:1901418

2024 Significance of area of hysteresis loop - Polymers Free Full

Polymers

Polymers, Free Full-Text